Introduction

Throughout history, stone has been a fundamental building material used in construction, architecture, and design. Its durability, timeless aesthetic appeal, and versatility have made it a popular choice for various projects. However, natural stone comes with its challenges, including cost, weight, and limited availability of certain types. In response to these challenges, the development of manufactured cultured stone has revolutionized the construction industry by offering a cost-effective, lightweight, and customizable alternative to natural stone. This article explores the evolution, production process, benefits, and applications of manufactured cultured stone.

Evolution of Cultured Stone

The concept of manufactured cultured stone can be traced back to the mid-20th century when innovative building materials were being developed to meet the growing demand for affordable and versatile construction materials. The first attempts at creating cultured stone involved using molds to replicate the appearance of natural stone. Over time, advancements in technology and materials science have led to the development of highly realistic and durable manufactured cultured stone products.

In the early days of cultured stone production, the focus was primarily on replicating the appearance of natural stone. However, as the industry evolved, manufacturers began to prioritize not only the aesthetics but also the performance and durability of the products. Today, manufactured cultured stone is engineered to mimic the texture, color, and shape of natural stone while offering additional benefits such as increased strength, reduced weight, and improved weather resistance.

Production Process

The production of manufactured cultured stone involves a meticulous process that combines innovative technology with skilled craftsmanship. The following steps outline the typical process of creating cultured stone:

1. Material Selection: High-quality raw materials such as cement, aggregates, and iron oxide pigments are selected to form the base of the cultured stone mixture. These materials are chosen for their durability, color consistency, and compatibility with the manufacturing process.

2. Molding: The selected materials are mixed together with water and poured into molds that are designed to replicate the desired shape and texture of the stone. The molds can vary in size and complexity, depending on the specific design of the cultured stone.

3. Curing: Once the mixture is poured into the molds, it undergoes a curing process to allow the materials to harden and set. This process may involve the application of heat or pressure to accelerate the curing time and ensure the strength and durability of the cultured stone.

4. Finishing: After the cultured stone has cured, it is removed from the molds and undergoes a finishing process to enhance its appearance and texture. This may involve sanding, polishing, or painting to achieve the desired aesthetic effect.

5. Quality Control: Throughout the production process, stringent quality control measures are implemented to ensure that each batch of cultured stone meets the required standards for strength, durability, and appearance. This includes testing for color consistency, texture uniformity, and structural integrity.

Benefits of Manufactured Cultured Stone

Manufactured cultured stone offers a wide range of benefits that make it a popular choice for various construction and design projects. Some of the key advantages of using cultured stone include:

1. Cost-Effective: Manufactured cultured stone is typically more affordable than natural stone, making it a cost-effective alternative for homeowners, builders, and designers. The production process of cultured stone allows for greater efficiency and consistency in manufacturing, resulting in lower production costs.

2. Lightweight: One of the significant advantages of manufactured cultured stone is its lightweight nature compared to natural stone. This makes it easier to transport, handle, and install, reducing labor costs and logistical challenges associated with heavy materials.

3. Customization: Cultured stone can be customized to meet specific design requirements, including color, texture, and shape. Manufacturers offer a wide range of options for customization, allowing builders and designers to create unique and personalized stone finishes for their projects.

4. Durability: Manufactured cultured stone is engineered to be highly durable and resistant to weathering, moisture, and impact. This makes it a long-lasting and low-maintenance building material that can withstand the elements and maintain its appearance over time.

5. Versatility: Cultured stone can be used in a variety of applications, including exterior cladding, interior walls, fireplaces, and landscaping features. Its versatility and adaptability make it a versatile choice for both residential and commercial projects.

6. Sustainability: The production of manufactured cultured stone involves using recycled materials and environmentally friendly manufacturing processes. This makes cultured stone a sustainable choice for environmentally conscious builders and designers looking to reduce their carbon footprint.

Applications of Manufactured Cultured Stone

Manufactured cultured stone is a versatile building material that can be used in a wide range of applications. Some common uses of cultured stone include:

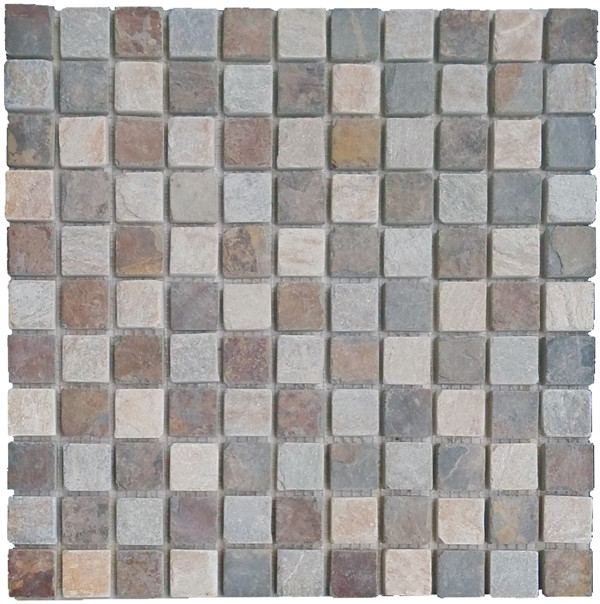

1. Flagstone stepstone pavers for natural beauty : Cultured stone is often used as a decorative and functional cladding material for exterior walls of residential and commercial buildings. Its natural appearance and durability make it an attractive choice for adding texture and visual interest to facades.

2. Interior Walls: Cultured stone can be used to create accent walls, fireplace surrounds, and feature walls in interior spaces. Its versatility in color and texture options allows designers to create unique focal points that enhance the overall aesthetics of a room.

3. Fireplaces: Cultured stone is a popular choice for fireplace surrounds and mantels, providing a rustic and cozy look to living spaces. The durability and heat-resistance of cultured stone make it a practical and stylish option for enhancing the ambiance of a room.

4. Landscaping Features: Cultured stone can be used to create outdoor landscaping features such as retaining walls, garden borders, and water features. Its natural appearance blends seamlessly with the outdoor environment, adding a touch of elegance and sophistication to outdoor spaces.

5. Architectural Details: Cultured stone can be used to create architectural details such as columns, archways, and cornices, adding character and charm to building exteriors. Its versatility in design options allows for the creation of custom-made elements that enhance the overall aesthetic appeal of a structure.

Conclusion

Manufactured cultured stone has transformed the construction industry by offering a cost-effective, lightweight, and customizable alternative to natural stone. With its realistic appearance, durability, and versatility, cultured stone has become a popular choice for builders, designers, and homeowners looking to enhance the aesthetics and functionality of their projects. As technology continues to advance, the future of manufactured cultured stone looks promising, with endless possibilities for innovative design solutions and sustainable building practices.